Candy making plant

plant Layout

Batch former

Rope sizer

THREE WAY COOLING CONVEYOR

Control panel

Candy Forming

Technical data

vacuum cooker

Application

Capacity

Batch Time

Steam Working Pressure

Drive

Vacuum Pump

Stirrer Speed

Dimensions (L X W X H)

Weight

Cooking and Vacuum

Available 50 Kg./ 100 Kg / 200 Kg Batch

20-25 Minutes/ Batch (Depending on Steam pressure and other allied conditions)

120 Lbs./ Sq. In. (According to Capacity)

Stirrer 1.5 H.P. (According to Capacity)

5 H.P (According to Capacity)

45-90 RPM

1200 X 1200X 2000 mm (According to Capacity)

Net 600 Kg. Gross 750 Kg. (According to Capacity)

Vacuum Batch Cooker is suitable for Candy Batch manufacturing. Now a days Toffee Batch is also prepared in Vacuum Cookers. The material is cooked in upper pan and after cooking the same is discharged into lower pan for vacuum and remove the moisture from the Batch

Cooling plate

Capacity

Water Requirement

Cooling Area

Dimensions (L X W )

Over all Size (L X W X H)

Weight

50 Kg / 100 kg / 200 Kg

1 Liter to 50 Liters per Hour

(Depending on efficiency of Cooling required and water temperature)

1524 mm X 914 mm

(According to Capacity)

1828 X 914 X 914 mm

(According to Capacity)

Net 500 Kg

(According to Capacity)

Water Cooling tilting type-cooling plate is useful for cooling and mixing of Lollipop/Candy and Toffee batch manually. The Cooling time is less on this plate then ordinary cooling plate because of continuous circulation of water inside the plate. If one side become hot, tilting the plate can use the other side.

batch roller (motorized lifting)

Capacity

Lifting

Rollers Drive

Heater

Discharge Height

Rope Diameter

Dimensions (L X W X H)

Weight

50 Kg / 90 kg

1 H.P. (According to Capacity)

0.5 H.P. (According to Capacity)

1000 watt

35 " (889 mm)

50-80 mm

1300 X 600 X 1700mm

(According to Capacity)

Net 700 Kg. Gross 1000 Kg

(According to Capacity)

Batch Former form conical shape of kneaded mixed and cooled batch of Lollypop / Candy / Toffee for further feeding into Rope Sizer. It is fitted with heaters to keep the batch warm. It's lifting and lowering mechanism helps the batch coming forward automatically. It is fitted with Stainless Steel Rollers. Electrical reverse and forward system is required extra for operating the batch former. There is ease of taking out rollers for cleaning operation.

Three stage

rope sizer

Speed

Application

Drive

Sizing Wheel Size

Dimension (L X W X H)

Weight

Maximum 60 meter rope/minute

Suitable for Lollypop / Ball-Lollipop / Candy forming

1 H.P. (A.C. or D.C.)

Input 33mm

Out 21 mm

800mm X 500mm X 1100mm

325 Kg

Three Stage rope sizer is suitable for Lollypop / Ball-lollipop / Candy Forming machines, which are equipped with two sets of sizer. It takes up rope from Batch roller and deliver to the rope sizer of Forming Machines

AUTOMATIC CANDY FORMING MACHINE (CAPACITY 2500 KG / SHIFT OF 8 HOURS)

Application

Capacity

Product Size

Minimum Candy Size

Maximum Candy Size

Dimension (L X W X H)

Drive

Weight

Forming of all type and shape of Hard Candies

2500 Kg/shift of Eight Hour

(Available in Capacity 1000 Kg / 1500 Kg / Shift)

(Depending upon Shape, Size and Weight of Candy)

12mm

40mm

1100 X 800mm X 1300mm

2 H.P. (A.C. or D.C.)

Net 600 KGS

Plast-O-Plast Candy Forming Machine is suitable for forming almost all type, sizes and shapes of Candies. Even the smallest size 12 mm. is possible in this machine. It can produce 2500 Kg of candy / shift depending on size, shape and weight of candy. The scrap formed is collected in a separate tray fitted on the machine and only candies are delivered to conveyor

THREE WAY COOLING CONVEYOR

Application

Drive

Blower

Dimension Wire mesh Belts

1st Belt

2nd Belt

3rd Belt

Dimensions (L X W X H)

Weight

Candy / Lollypop / Chupa-Chup Cooling upto 2.5 Ton/Shift.

Wire mash drive from the forming machine.

3. H.P. A.C.

16 Feet X 100 mm

12 Feet X 200 mm

12 Feet X 300 mm

5000 mm X 500 mm X 900 mm

Net 850 Kg.

Three Way Conveyor is suitable for all type of Forming Machine having production capacity up to 2.5 Ton/Shift. In three way cooling conveyor the candies will be cooled and accurate in shape. The wire mash tensioning system is very easy and simple

PANEL BOARD

Application

Dimensions (L X W X H)

Weight

Panel Board Candy, Toffee, Lollipop

1830 mm X 915 mm X 400 mm

Net 300 Kg

Panel Board will install back side rope Sizer where a single man can operate Batch Roller, Rope Sizer, Forming Machine and Three way Cooling Conveyor by pressing a single Button

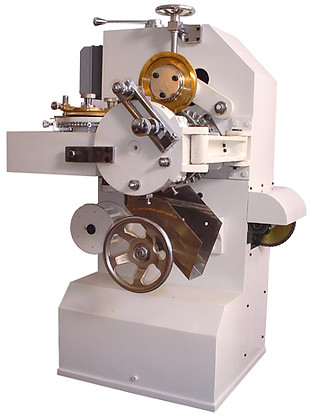

AUTOMATIC CANDY WRAPPING MACHINE

Application

Capacity

Drive

Heaters

Dimensions (L X W X H)

Weight

Candy Wrapping (Double End Twist)

Wrapping

300 PCs/Min

2 HP A.C. or D.C.

2 kW

1600 x 1450 x 1650

Net 1000 Kg.

Candy wrapping Machine is suitable for twist wrapping of hard-boiled candies. The paper is also automatically cut into required lengths and candies are individually wrapped in this paper

CANDY PACKING (PILLOW-TYPE) PACKING

Application

Capacity

Drive

Heaters

Dimensions (L X W X H)

Weight

Candy Packing (Pillow-type packing)

600 PCs/Min

2 HP A.C. or D.C.

3 kW

1750 x 950 x 1550

Net 700 Kg. Gross 800 Kg.

Pillow Packing Candy Packing Machine is suitable for Pillow type packing for hard-boiled candies. Pillow-Pack is installed with Photo-Eye Mark censer. Pillow-Pack keep Candies Fresher for long period of time